Standard Kitchen Cabinet Door Sizes and Variations

The seemingly mundane task of measuring kitchen cabinet doors reveals a complex landscape of standardization, variation, and ultimately, the subtle power dynamics at play in the kitchen cabinet industry. While ostensibly simple, the dimensions of these doors reflect a history of manufacturing practices, consumer preferences, and the inherent compromises between efficiency and customization. The following analysis dissects this seemingly innocuous aspect of kitchen design, exposing the inherent inconsistencies and the lack of true standardization within the market.

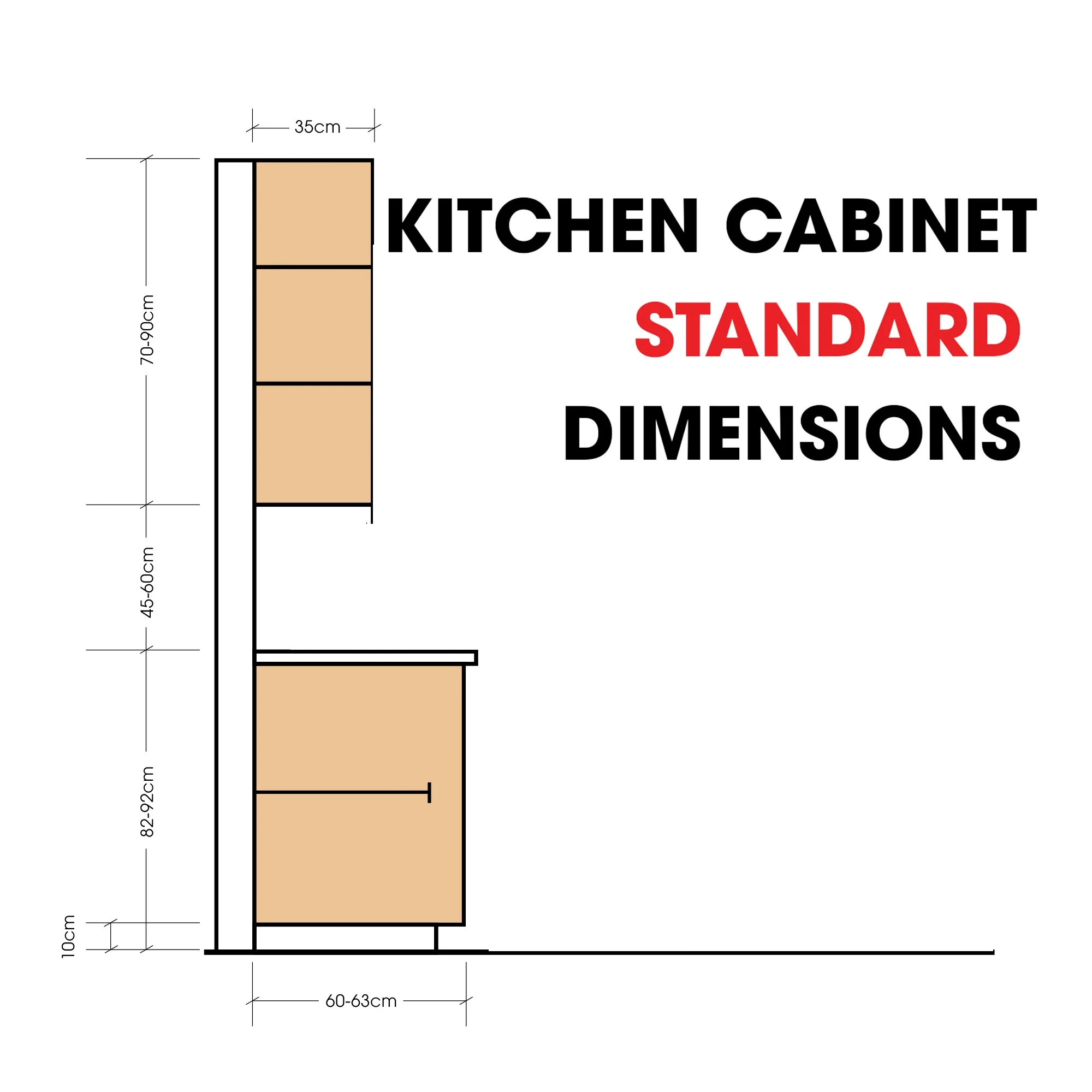

Standard Kitchen Cabinet Door Sizes

The illusion of standard kitchen cabinet door sizes is perpetuated by industry brochures and online retailers. However, a closer examination reveals significant discrepancies. The following table offers a glimpse into the supposed “standards,” but it is crucial to understand these are broad generalizations, not industry-wide mandates. Individual manufacturers frequently deviate, often significantly.

| Cabinet Type | Height (inches) | Width (inches) | Depth (inches) |

|---|---|---|---|

| Base | 34.5 – 36 | 9 – 36 | 1.5 – 2.25 |

| Wall | 12 – 30 | 9 – 36 | 1.5 – 2.25 |

| Corner | 34.5 – 36 | Variable (depending on configuration) | 1.5 – 2.25 |

Variations in Door Sizes Across Manufacturers

The table above highlights a critical issue: the lack of a truly unified standard. Differences in manufacturing processes, material choices (solid wood versus particleboard), and even the preferred design aesthetics of individual companies lead to inconsistencies. A 36-inch base cabinet door from one manufacturer might have a slightly different depth or a subtly different width compared to a similar cabinet from another. This seemingly small variation becomes a significant issue when planning a kitchen remodel, requiring careful attention to detail and often necessitating compromises. The absence of a robust, universally enforced standard empowers manufacturers to prioritize their own internal efficiencies over genuine standardization.

Impact of Door Style on Dimensions, Kitchen cabinet door measurements

The style of the cabinet door significantly influences its dimensions. A simple slab door will have different dimensional requirements than a more intricate shaker or raised panel door. The added detailing of raised panels, for example, requires additional material and, consequently, can affect the overall width and height. Shaker doors, with their characteristic recessed panels, may also present subtle variations in dimensions compared to slab doors. These variations, although often subtle, must be factored into any accurate measurement and planning process. The lack of transparency in how these style differences impact overall dimensions further complicates the process for consumers.

Example Kitchen Layout

Imagine a kitchen with a 10-foot long countertop. A typical layout might include three base cabinets: a 36-inch sink base, a 30-inch drawer base, and a 24-inch base cabinet. Above, wall cabinets of varying sizes (e.g., 30-inch, 24-inch, and 18-inch) might be arranged. Corner cabinets, often customized to fit the space, will have their own unique dimensional challenges. Each of these cabinets, regardless of its type, will have doors with dimensions reflecting the cabinet’s size and the manufacturer’s particular specifications, underscoring the lack of a truly unified standard. This scenario demonstrates the inherent complexities of working with what is presented as a simple system of standardized dimensions.

Measuring Existing Kitchen Cabinet Doors for Replacement

Replacing kitchen cabinet doors is a cost-effective way to revitalize a kitchen’s aesthetic. However, inaccurate measurements can lead to costly mistakes and frustrating delays. Precision is paramount; this process demands meticulous attention to detail, leaving no room for the amateurish guesswork often tolerated in other home improvement projects.

Step-by-Step Guide to Accurate Measurement

Accurate measurement requires a systematic approach. First, ensure the cabinet doors are fully closed and level. Any warping or unevenness will skew measurements. We will measure height, width, and depth individually. Begin with height, measuring from the top edge of the door to the bottom edge. Record this measurement to the nearest 1/16th of an inch using a high-quality measuring tape. Repeat this process for width, measuring across the widest part of the door. Finally, measure the depth, which is the thickness of the door, at its thickest point. This three-pronged approach is crucial for ensuring a perfect fit. For example, imagine measuring a door that is slightly bowed – failing to account for this could lead to a replacement door that doesn’t close properly.

Common Measurement Errors

Numerous pitfalls can sabotage even the most well-intentioned measuring efforts. One prevalent error is failing to account for the existing door’s frame or overlay. An overlay door extends slightly beyond the cabinet frame, influencing the final measurement needed for a replacement. Similarly, neglecting to measure multiple doors of the same size to confirm consistency is a frequent oversight. Minor discrepancies between doors, often overlooked, can accumulate and render a set of replacement doors unusable. Lastly, rounding measurements up or down rather than recording precise measurements to the nearest 1/16th of an inch can lead to a final product that is either too loose or too tight.

Necessary Tools and Equipment

Precision demands the right tools. A high-quality measuring tape capable of measuring to 1/16th of an inch is essential. A metal ruler, offering superior straightness and accuracy compared to a flexible tape measure, should be used for verifying measurements, especially in the case of unusually shaped doors. A pencil for marking measurements on the door is also necessary. Additionally, a level can help ensure the door is properly positioned for measurement, and a notebook or digital recording device to note all measurements will aid in organization and prevent errors. Finally, a digital caliper can provide exceptional accuracy for measuring the thickness of the door, especially important for doors with intricate detailing or molding.

Comparison of Measurement Methods

| Measurement Method | Advantages | Disadvantages |

|---|---|---|

| Standard Measuring Tape | Readily available, relatively inexpensive. | Potential for inaccuracy due to flexibility, particularly for larger doors. Measurements may be slightly less precise than other methods. |

| Metal Ruler and Measuring Tape Combination | Combines the straightness of a ruler for verification with the convenience of a tape measure for initial measurements. | Slightly more time-consuming than using a tape measure alone. |

| Digital Caliper | Offers the highest level of precision, particularly for depth measurements. | More expensive than other methods. Requires a degree of technical proficiency to operate correctly. |

Custom Kitchen Cabinet Door Ordering and Specifications: Kitchen Cabinet Door Measurements

Navigating the world of custom kitchen cabinet doors can feel like wading through political mudslinging – opaque processes, hidden costs, and a general lack of transparency. However, understanding the process empowers consumers to avoid being manipulated and ensures they receive exactly what they need. This section cuts through the corporate jargon and provides a clear path to ordering your custom doors.

The process of ordering custom-sized kitchen cabinet doors involves several crucial steps. First, precise measurements are paramount. Any error here will cascade into a costly mistake. Second, selecting the right manufacturer or supplier is vital. Research their reputation, examine their portfolio, and verify their production capabilities. Third, clear and unambiguous communication of specifications is essential to prevent misunderstandings and delays. Finally, carefully review the order confirmation to ensure all details are correct before production begins. Failure to do any of these steps can result in significant delays, extra costs, or even unusable doors.

Custom Cabinet Door Specification Template

A precise specification template is crucial for avoiding costly errors. Ambiguity invites misinterpretations and delays. This template ensures all necessary information is provided upfront. Remember, clarity is king in this process.

| Item | Specification |

|---|---|

| Quantity | Number of doors needed |

| Height (inches) | Precise height of each door |

| Width (inches) | Precise width of each door |

| Depth (inches) | Depth of the door (including any overlays) |

| Material | Specify wood type, veneer, or other material (e.g., solid maple, cherry veneer, MDF) |

| Style | Detailed description of the door style (e.g., Shaker, raised panel, flat panel, beaded inset, etc. Include specifics like rail and stile profiles, panel details) |

| Finish | Specify the desired finish (e.g., paint color, stain color, clear coat) Include color codes where possible. |

| Hardware | Specify any required hardware (e.g., hinges, knobs, pulls) including type, finish, and quantity. |

Calculating Total Number of Cabinet Doors

Accurate door counts prevent shortages or unnecessary expenses. Begin by meticulously measuring each cabinet opening. Record the measurements for each cabinet and then determine the number of doors required for each. This process should be systematic and avoid assumptions. For example, a base cabinet might require two doors, while an upper cabinet might only need one. Double-check all measurements and calculations to minimize errors. Remember, a simple mistake can lead to significant rework.

Custom Kitchen Cabinet Door Order Form

This sample order form streamlines the ordering process and minimizes the chance of errors. Complete all fields accurately. Any omissions or ambiguities can delay production and potentially compromise the final product. The clarity of this form is intended to mirror the clarity that should exist in the entire process.

Kitchen cabinet door measurements – The following fields are required for a complete order:

- Customer Name and Contact Information

- Project Address

- Date of Order

- Number of Doors

- Door Height (inches) – per door

- Door Width (inches) – per door

- Door Depth (inches) – per door

- Material (e.g., wood type, veneer)

- Style (e.g., Shaker, raised panel, with detailed specifications)

- Finish (e.g., paint color with code, stain color)

- Hardware Type and Quantity

- Delivery Address

- Expected Delivery Date

- Total Cost